Granules on shingles: their function and how they are made

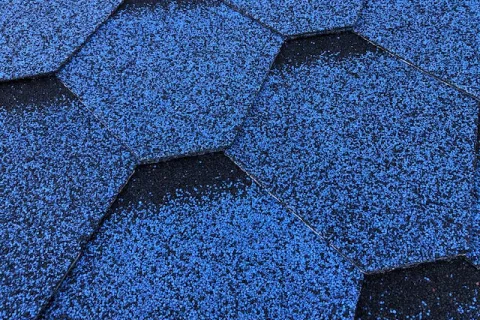

Roofing granules are one of the basic components of bitumen roof shingles. They give them an aesthetical appeal. A combination of colors often results in a creative look. The aesthetic function and appearance of granules is important but there is an even more prime role of shingle granules.

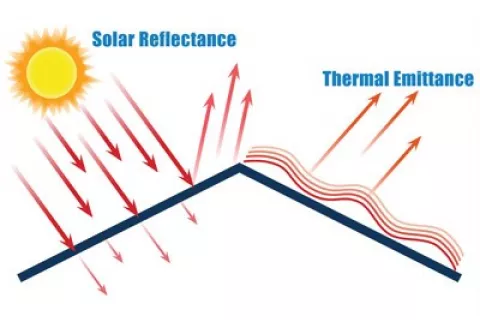

Roofing granules work as a shield, protecting the integrity of the shingle from the outside elements. More specifically granules protect and preserve the bitumen shingle from solar ultraviolet radiation. They are designed to protect the asphalt coating of shingles from harsh UV sunlight. Some lighter colors and special reflective granules can also make your roof cooler which results in lower energy and utility bills.

Granules, which are predominantly manufactured using natural stone, are crushed, screened and sized to various gradation sizes. This goes from very small particles (0,425 mm) to the larger particles (1,7 mm) with multiple groups of sizes in between, all selected in specific percentages of the overall granule blend mixture. These granules are manufactured in such a way that when applied to and embedded in the shingles asphalt coating, the particles interlock together in order to provide the absolute maximum coverage of the asphalt. There is also the advantage that more rounded granules hold better in the asphalt coating compared to the flat shape e.g. granules produced from the slate

The production of colored granules is basically a process where the blended stones with different sizes are coated with a combination of organic and/or inorganic pigments similar to paint. The pigment mixture, once applied to the stone, is baked on at high temperatures causing the pigment color to be fused to the stone in a ceramic process. The selection of the type and quantity of pigments utilized will determine the final appearance and color of the granules. Once the roofing granules are cooled, they undergo a rigorous set of tests to certify the quality and longevity of the product.

Controlling of granule drops behind the coater

Color fixation tests are performed to make certain that the pigmentation has adhered properly to the stone and to ensure that the color will remain stable over time. Sometimes the color may slightly fade but historically roofing granules have proven to be relatively color-stable. IKO granules are made from volcanic stone basalt, which means that sometimes the natural stone from one part of stone-pit can be darker as from another part. It means that pigments can penetrate some lighter parts of stone less and that’s why we at IKO always recommend to mix bitumen shingles from different bundles during the installation process. This avoids color blocks on the roof. Many other tests are also done on the colored granules such as testing for asphalt staining, water repellence or moisture content. It’s very important due to another defect on shingles called blistering.

Although the particle size distribution and coloring processes are of crucial importance, the selection of the natural stone itself is in fact just as important. Several characteristics are essential when analyzing and selecting an appropriate and suitable stone. The main qualities that are required are hardness, opacity to UV sunlight and the amount of iron content. In other words, an acceptable stone for granules must be durable as well as opaque and rust-resistant.

1. Hardness

A suitable stone must be sufficiently hard, otherwise once coated the natural stone could break apart or even fracture during the manufacturing process or by roofers and homeowners walking on the shingles during or after their installation. The majority of natural stones are simply too soft to be suitable for colored roofing granules. Fragile stones such as calcite, dolomite or slate would break apart which would lead to exposure of the uncolored interior portion of the stone and possibly to premature mineral granule loss.

2. Opacity to UV rays

Opacity to solar ultraviolet rays is the ability of the stone to prevent or allow light to pass through it. The best stones are the darker ones as e.g. basalt. Typically a granite or quartz type stone lets light pass through easier than a darker stone which is not good. Even though colored roofing granules are surface-coated, the ability of the granule to prevent light transmission is determined by the base rock, not by the ceramic color coating. UV rays which pass through the granules would lead to premature degradation of the asphalt coating which adheres the granule to the shingle.

3. Iron content

A third but equally important characteristic is the degree of iron content found in stone. To be suitable a stone should have only a small amount of iron in its composition. This to prevent iron from leaking out from granules, which can lead to rust stains on a roof.

Elements that can have an effect on roofing granules

There are several factors that can cause granules to loosen and be removed from bitumen roof shingles.

- Cleaning the roof with high water pressure can blast granules from roof shingles.

- Extensive winds, storms or heavy rainfall can also be factors

- Small hail can displace roofing granules.

- Any foot traffic can cause granules to remove.

My gutter is filled with granules. Is there a problem with my shingles?

Not necessarily. An excessive amount of granules are applied during the shingle manufacturing process to make sure that the bitumen on the roofing sheet is completely covered. It is important to completely cover the sheet with granules so that the bitumen is not exposed to ultraviolet light. In accordance to the EN 544 the value of the loss of granules may not exceed 2,5 g (test procedure EN 12039). But IKO does better than that. IKO’s own maximum limited value is 1,2 g!

Aspects and warnings

- It is not a mistake if a couple of granules appear after a storm if your roof isn’t that old. But if your roof is old and most of the granules are peeled off, you should consider replacing it as this can be a big concern.

- The easiest way to do this is to be physically on the roof and check the asphalt shingles. If you see many spots without granules and there is only the top coating of bitumen left, it could mean that it’s time to replace your shingles.

- Remember that regular maintenance and inspection of your roof will extend its life by many years.

Resume

Roofing granules are made from crushed stone and minerals. With today's advanced manufacturing techniques, these granules allow roofing manufacturers to create asphalt shingles of virtually any color, size and shape. These small colored stones are one of the most important parts in the composition of asphalt shingles together with bitumen as well as the supporting inlay from fiberglass. Learn more about the shingle production process.

Want to take a closer look to certain colours of our range? Request up to 3 A4 samples!